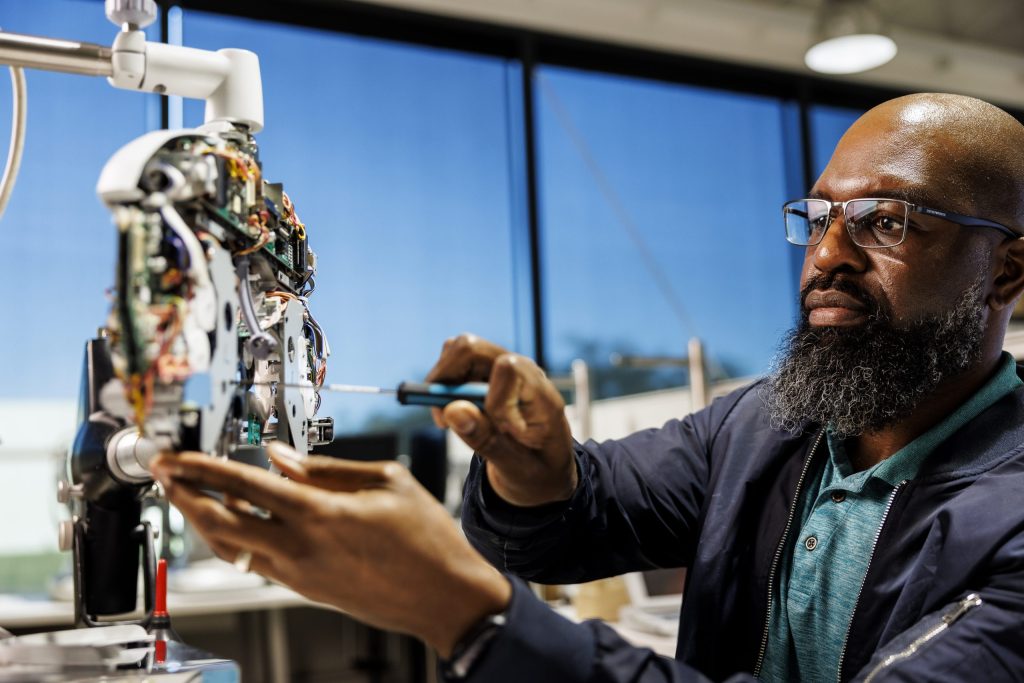

Reduce unexpected downtime and protect your investment by scheduling preventative maintenance.

Let our manufacturer-trained technicians service your equipment to ensure peak performance.

Complete Exam Lane Tune-Up

- Check and adjust alignment of all moving parts

- Inspect all wires, connections and hydraulic components

- Verify slit lamp operations by setting to factory standards, leveling table, and cleaning base to ensure smooth movement

- Test all handhelds and BIOs

- Exterior cleaning

Lens Finishing (Edgers and Blockers)

- Conduct a thorough, 56-point inspection

- Complete cleaning, inside and out

- Calibration of all lens materials, apply lubrication, and make required adjustments

- Ensure software is current (free software updates)

- Review daily, weekly, and monthly maintenance practices with staff

Pre-Test and Diagnostic Instruments

- Thoroughly inspect instruments for potential issues or areas for improvement

- Check objective lenses and sensors

- Test instrument movements to ensure smoothness

- Exterior cleaning

Phoropter Cleaning & Reconditioning*

- Perform a complete disassembly and reconditioning

- Inspect and clean sphere lenses, auxiliary lenses, and prisms

- Degrease and relubricate all moving parts and bearings

- Correct misalignments and calibrate to correct factory standards

*Performed at service center. Loaner phoropter based on availability.

Complete Exam Lane Tune-Up

- Check and adjust alignment of all moving parts

- Inspect all wires, connections and hydraulic components

- Verify slit lamp operations by setting to factory standards, leveling table, and cleaning base to ensure smooth movement

- Test all handhelds and BIOs

- Exterior cleaning