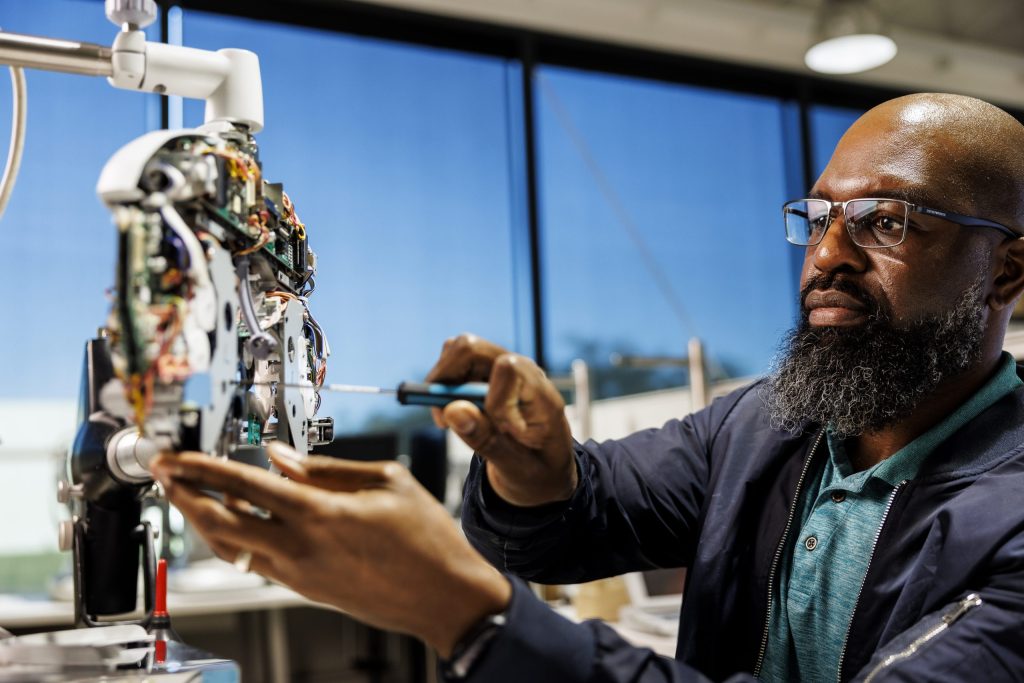

Just like regularly scheduled car maintenance, regularly scheduled equipment maintenance is essential to ensure your equipment is performing at its peak.

Reduce unexpected downtime and protect your investment by scheduling preventative maintenance. Let our manufacturer-trained technicians service your equipment to ensure peak performance.

Complete Exam Lane Tune-Up

- Check and adjust alignment of all moving parts

- Inspect all wires, connections and hydraulic components

- Verify slit lamp operations by setting to factory standards, leveling table, and cleaning base to ensure smooth movement

- Test all handhelds and BIOs

- Exterior cleaning

ADD Lens Finishing

- 56-point detailed inspection

- Calibration, lubrication, and adjustments

- Free equipment software upgrades

Pre-Test and Diagnostic Instruments

- Thoroughly inspect instruments for potential issues or areas for improvement

- Check objective lenses and sensors

- Test instrument movements to ensure smoothness

- Exterior cleaning

Phoropter Cleaning & Reconditioning*

- Perform a complete disassembly and reconditioning

- Inspect and clean sphere lenses, auxiliary lenses, and prisms

- Degrease and relubricate all moving parts and bearings

- Correct misalignments and calibrate to correct factory standards

*Performed at service center. Loaner phoropter based on availability.

Complete Exam Lane Tune-Up

- Check and adjust alignment of all moving parts

- Inspect all wires, connections and hydraulic components

- Verify slit lamp operations by setting to factory standards, leveling table, and cleaning base to ensure smooth movement

- Test all handhelds and BIOs

- Exterior cleaning